As Thanksgiving approaches, we at Robotiq are especially thankful for the Food & Beverage manufacturers, operators, engineers, and integrators who work tirelessly every day to keep production moving.

We’re also grateful for the power of smart automation: technology that doesn’t just boost output, but protects people, improves quality, and makes factories safer and more sustainable.

To celebrate, we’re sharing five real-world stories where Robotiq’s collaborative palletizing solutions have made a meaningful impact. These examples show what’s possible when automation and human talent work hand in hand.

1. Glenhaven Foods: Fast ROI, safer operators

The Challenge: Glenhaven Foods faced high labor costs and ergonomic strain from manual palletizing of frozen meals. They needed a solution that could handle dozens of SKUs without compromising worker safety.

The Solution: By implementing Robotiq’s PE20 Lean Palletizer, Glenhaven Foods automated 15 boxes per minute across 25 SKUs. The system was up and running quickly, with minimal training required.

The Result: Operators were freed from repetitive, high-strain tasks, productivity increased, and the ROI was achieved in just 13 months. Lean Palletizing became an integral part of their operations, supporting both output and workplace safety.

2. RAIN Pure Mountain Spring Water: Reducing strain, boosting throughput

The Challenge: RAIN Pure Mountain Spring Water’s operators were lifting heavy 30-pound boxes in a compact facility, a physically demanding task that contributed to fatigue and turnover.

The Solution: Robotiq’s compact palletizing solution enabled safe, collaborative automation right alongside human operators.

The Result: Through automation, operators were reassigned to higher-value tasks, throughput increased, and ergonomic risks were significantly reduced. This allowed the team to focus on what matters most: consistent quality and efficiency.

3. Griffith Foods Colombia: Eliminating thousands of repetitive motions

The Challenge: Repetitive manual stacking was creating fatigue, ergonomic risks, and slowdowns on multiple production lines with many SKUs.

The Solution: Lean Palletizing, powered by Robotiq cobots, replaced thousands of daily repetitive motions with automated precision.

The Result: Operators now enjoy safer, less physically demanding work, while the production line runs more consistently. Safety and productivity went hand in hand, proving that even repetitive, “back-of-line” tasks can benefit from automation.

4. Panovo (Grupo Proan): Handling tall stacks with ease

The Challenge: Bakery production lines faced high pallet stacks (up to 2.5 meters/ 8+ feet), causing fatigue and inconsistent pallet quality.

The Solution: Five AX10 cobots were deployed to handle palletizing, with carefully engineered configurations to manage tall stacks safely.

The Result: The cobots consistently stack tall pallets without fatigue or error, improving workflow, operator well-being, and pallet stability. Panovo now runs a smoother operation while keeping employees out of risky manual tasks.

5. Korea Pelagic: Automation in a cold, demanding environment

The Challenge: Seafood processing requires handling heavy, cold items with limited workforce availability and high turnover risk. Manual palletizing was slow, unsafe, and inconsistent.

The Solution: Robotiq cobots automated palletizing in the cold environment, working safely alongside humans.

The Result: Productivity increased by 200%, labor strain decreased, and turnover stabilized. Operators can focus on higher-value tasks, while cobots handle repetitive, physically demanding work.

Why these stories matter

Across these five case studies, a few clear patterns emerge:

- Automation protects people: From heavy lifting to repetitive motions, cobots handle high-risk tasks safely.

- Automation supports business growth: Increased throughput, predictable ROI, and faster commissioning make these investments worthwhile.

- Automation complements human talent: Operators are freed for higher-value work, leading to safer, more engaging jobs and lower turnover.

At Robotiq, we regularly share these real-world customer stories to show what’s possible when humans and robots work together.

A Thanksgiving Message

This holiday season, we’re thankful for all the Food & Beverage teams who make innovation, safety, and efficiency a reality.

From Glenhaven Foods’ fast ROI to Korea Pelagic’s cold-environment success, these stories remind us why automation is about more than machines; it’s about supporting the people who make factories thrive.

Here’s to full pallets, safer workflows, and smarter operations this Thanksgiving.

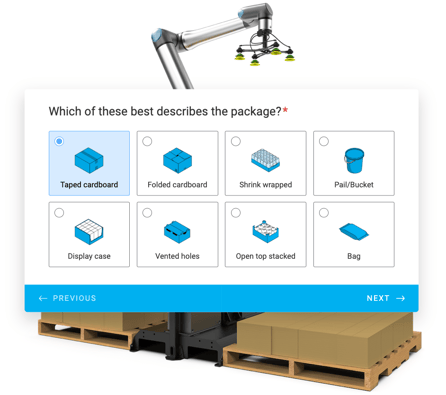

Discover your own path to safer, smarter palletizing. Try the Palletizing Fit Tool — a quick, interactive way to see if Lean Palletizing is the right match for your line.

Want more stories from real factories like yours?

Follow Robotiq on LinkedIn and join over 75,000 manufacturers seeing how automation keeps people safe, and production running strong.

![]()

The post “This Thanksgiving, we’re thankful for innovation and the teams making it happen” by Linnea Bruce was published on 11/25/2025 by blog.robotiq.com

.jpg)