Less than three years ago, these were bare fields in humble Ellabell, Georgia. Today, the vast Hyundai Motor Group Metaplant is exactly what people imagine when they talk about the future of EV and automobile manufacturing in America.

I’ve driven the 2026 Hyundai Ioniq9 here from nearby Savannah, a striking three-row electric SUV with everything it takes to succeed in today’s market: Up to 530 kilometers (335 miles) of efficient driving range, the latest features and tech, and a native NACS connector that lets owners—finally—hook into Tesla Superchargers with streamlined Plug and Charge ease.

The success of the Ioniq9 and popular Ioniq5 crossover is deeply intertwined with the US $7.6 billion Metaplant, whose inaugural 2025 Ioniq5 rolled off its assembly line in October. That includes the Ioniq models’ full eligibility for $7,500 consumer tax credits for U.S.-built EVs with North American batteries, although the credits are on the Trump administration’s chopping block. Still, the factory gives Hyundai a bulwark and some breathing room against potential tariffs, and puts the South Korean automaker ahead of many rivals.

America’s Largest EV Plant

With 11 cavernous buildings and a massive 697,000 square meters (7.5 million square feet) of space, it’s set to become America’s largest dedicated plant for EVs and hybrids, with capacity for 500,000 Hyundai, Kia and Genesis models per year. (Tesla’s Texas Gigafactory can produce 375,000). Company executives say this is North America’s most heavily automated factory, bar none, a showcase for AI and robotic tech.

The factory is also environmentally friendly, as I see when I roll into the factory: “Meta Pros,” as Hyundai calls its workers, can park in nearly 1,900 spaces beneath solar roofs, shielded from baking Georgia sun that provides up to five percent of the plant’s electricity. The automaker has a target of obtaining 100 percent of its energy from renewable sources. Those include hydrogen trucks from the Hyundai-owned Xcient, the world’s first commercialized hydrogen fuel-cell semis. A fleet of 21 trucks haul parts here from area suppliers, taking advantage of 400-kilometer driving ranges with zero tailpipe emissions. The bulk of finished vehicles are shipped by rail rather than truck, trimming fossil-fuel emissions and the automaker’s carbon footprint.

At the docks, some of the plant’s 850 robots unload parts from the hydrogen trucks. About 300 automated guided vehicles, or AGVs, glide around the factory with no tracks required, smartly avoiding human workers. As part of an AI-based procurement and logistics system, the AGVs automatically allocate and ferry parts to their proper work stations for just-in-time delivery, saving space, time, and money otherwise used to stockpile parts.

“They’re delivering the right parts to the right station at the right time, so you’re no longer relying on people to make decisions,” says Jerry Roach, senior manager of general assembly.

The building blocks of a modern unibody car chassis, called “bodies in white,” are welded by an army of 475 robots at Hyundai’s new plant.Hyundai

I’ve seen AGVs in action around the world, but the Metaplant shows me a new trick: A pair of sled-like AGVs slide below these electric Hyundais as they roll off the line. They grab and hoist their wheels, and autonomously ferry the finished Hyundais to a parking area, with no need for a human driver.

Robotic Innovations in Hyundai Factories

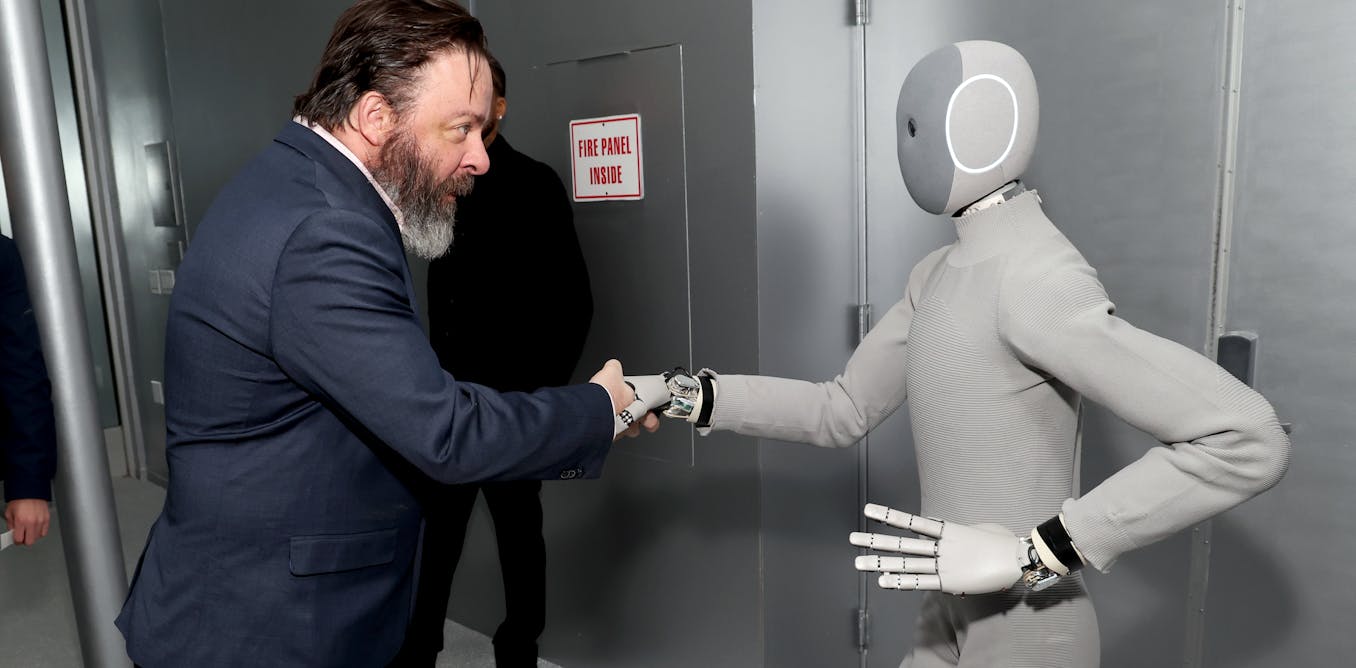

Some companies have strict policies about pets at work. Here, Spots—robotic quadrupeds designed by the Hyundai-owned Boston Dynamics—use 360-degree vision and “athletic intelligence” to sniff out potential defects on car welds. Those four-legged friends may soon have a biped partner: Atlas, the humanoid robots from Boston Dynamics whose breathtaking physical skills—including crawling, cartwheeling, and even breakdance moves—have observers wondering if autoworkers are next in line to be replaced by AI. Hyundai executives say that’s not the case, even as they plan to deploy Atlas models (non-union of course) throughout their global factories. With RGB cameras in their charming, 360-degree swiveling heads, Atlas robots are being trained to sense their environments, avoid collisions, and manipulate and move parts in factories in impressively complex sequences.

The welding shop alone houses 475 industrial robots, among about 850 in total. I watch massive robots cobble together “bodies in white,” the building blocks of every car chassis, with ruthless speed and precision. A trip to the onsite steel stamping plant reveals a facility so quiet that no ear protection is required. Here, a whirling mass of robots stamp out roofs, fenders, and hoods, which are automatically stored in soaring racks overhead.

Roach says the Metaplant offered a unique opportunity to design an electrified car plant from the ground up; rather than retrofit an existing factory that made internal-combustion cars, which even Tesla and Rivian were forced to do in California and Illinois respectively.

Regarding automation replacing human workers, Roach acknowledges some of it is inevitable. But robots are also freeing humans from heavy lifting and repetitive, mindless tasks that, for decades, made factory work both hazardous and unfulfilling.

He offers a technical first as an example: A collaborative robot—sophisticated enough to work alongside humans with no physical separation for safety—installs bulky doors on the assembly line. It’s a notoriously cumbersome process to perform without scratching the pretty paint on a door or surrounding panels.

“Guess what? Robots do that perfectly,” Roach says. “They always put the door in the exact same place. So here, that technology makes sense.”

It also frees people to do what they’re best at: Precision tasks that require dexterous fingers, vision, intelligence, and skill. “I want my people doing craftsmanship,” Roach says.

The plant currently employs 1,340 Meta Pros at an annual average pay of $58,100. That’s 25 percent higher than average in Bryan County, Ga. Hyundai’s annual local payroll has already reached $497 million. The company foresees an eventual 8,500 jobs on site, and another 7,000 indirect jobs for local suppliers and businesses.

On the battery front, Hyundai is currently sourcing cells from Georgia and SK On, with some Ioniq5 batteries imported from Hungary. But the Metaplant campus includes the HL-GA battery company. The $4 billion plant, an joint operation with LG Energy Solutions, plans to produce nickel-cobalt-magnesium cells beginning next year, assembled into packs on site by Hyundai’s Mobis subsidiary. Hyundai is also on track to open a second $5 billion battery plant in Georgia, a joint operation with SK On. It’s all part of Hyundai’s planned $21 billion in U.S. investment between now and 2028—more than the $20 billion it invested since entering the U.S. market in 1986. Even a robot could crunch those numbers and come away impressed.

The post “Hyundai's Metaplant Seeks Hard-Working Robots” by Lawrence Ulrich was published on 05/28/2025 by spectrum.ieee.org