When you walk into Cascade Coffee’s facility north of Seattle, you immediately sense two things: the unmistakable smell of freshly roasted beans, and a team that’s genuinely proud of the work they do.

That second part didn’t happen by accident.

It’s the result of a bold decision Cascade made about four years ago: replace one of the most painful, turnover-heavy, inconsistent manual jobs in the factory with collaborative robots. What started as a single low-risk experiment snowballed into a systematic, company-wide transformation touching productivity, people, and culture.

I recently sat down with Cascade’s COO, Ron Kane, to retrace that journey. Ron’s spent more than 30 years in food and beverage—Nestlé Waters, Monster Energy, craft beer—so he’s seen every flavor of automation project, from the successful to the painful. His perspective is extremely grounded in what manufacturers live every day.

Here’s Cascade’s story, and the lessons any food and bev factory can apply.

When growth meets reality

In 2020, Cascade shifted from serving one major customer (80% of their volume) to supporting a broad portfolio of brands, especially innovative ecommerce players. It unlocked growth, but increased complexity overnight.

The problem? Nearly everything downstream was still manual.

- Operators were hand-stacking dozens of pallet configurations

- Turnover at the palletizing role was over 60%

- New hires were trained almost weekly on intricate customer-specific patterns

- Quality errors—like misaligned labels on shipments—were eroding customer satisfaction

And culturally, nobody wanted the palletizing job. It was physically demanding, low variety, and stressful.

“It didn’t provide value for us as a factory. It needed to be done, but it really should have been automated if there was a way to do it.”

– Ron Kane, COO

The challenge was the same one many mid-sized manufacturers face: traditional palletizers were too big, too expensive, and too complex for their footprint.

The first leap: A practical, low-risk test

When Cascade purchased a new high-volume K-Cup line, Ron saw an opportunity: if they were upgrading processing and packaging, why stop there?

He evaluated the full picture: labor, ergonomics, turnover, uptime, and customer requirements and proposed trialing a cobot palletizer. The initial ROI estimate was just under two years, already solid.

What happened next surprised everyone.

Their local partner, Olympus Controls, rolled the system into place. Within hours, it was bolted down. By the next afternoon, it was palletizing live production.

No cages. No complex programming. No weeks of commissioning.

Operators learned the interface in minutes. The safety behavior immediately earned their trust. And the cultural shift happened faster than expected: the team named the robot, decorated it for holidays, and treated it as an additional coworker.

“We installed the robot, didn’t lose any headcount, and it became part of the personality of the factory.”

Nine months to payback, not two years

When the first audit was complete, the numbers came in…

Actual ROI: 9 months.

Why the dramatic difference?

- Higher uptime than expected

- Consistent throughput, even during variable volume

- No unplanned labor coverage for downtime

- Fewer quality issues

- Rising volume on the line

In three years, Ron can count on one hand the number of days any palletizer has been down. And those rare issues? Usually from packaging anomalies, not the robot.

That reliability became the reason Cascade could scale confidently.

Scaling systematically: From one to six (and counting!)

-2.jpg?width=685&height=385&name=Robotiq%20Background%20(Cascade%20Coffee)-2.jpg)

Once the first cell proved itself, Cascade replicated the approach across every retail bag line in the factory.

Because their mechanics and engineers already understood the interface, subsequent installations became nearly plug-and-play:

- Still delivered in crates

- Still bolted down in hours

- Still operational the next day

- Still easy to troubleshoot independently

One line went from crate arrival to running production by the end of the first shift.

And their team started collaborating with our engineers on performance upgrades—like early adoption of dual-case picking to boost throughput without increasing speed.

The result was: a standardized, repeatable palletizing strategy across the entire site.

Real business impact: Millions saved, people lifted up

Cascade Coffee invested just under seven figures across all systems.

They’ve already recouped multiple millions in labor efficiency.

But the part Ron speaks about with the most pride isn’t the financial return; it’s the people.

The employees who once rotated through the hardest job in the plant are still there. Many have moved up to higher-skill roles.

“They’re building careers, not just doing jobs. They’re earning more for their families. They’re more confident operating bigger equipment because they learned on the cobot first.”

Automation didn’t reduce headcount. It actually created new opportunity.

And it was a great fit culturally as well. The robots have names, holiday outfits, and recurring appearances on Cascade’s LinkedIn page. They’ve become part of the team!

Lessons for manufacturers considering automation

Here are the takeaways Ron would give anyone just starting their automation journey:

1. Your real ROI will likely be better than your spreadsheet.

Manufacturers often underestimate the effect of consistent throughput and overestimate downtime risk.

2. Start where the pain is highest and the labor is toughest to retain.

Palletizing jobs burn people out quickly. Solving that pain benefits the whole operation.

3. Culture matters as much as technology.

Communicate clearly that automation removes undesirable tasks—not people.

4. Standardize early.

Once one cell is running well, you can replicate it efficiently across similar lines.

5. A strong local partner makes all the difference.

Olympus Controls helped Cascade deploy fast and adapt quickly, even as needs changed.

What this story really shows

Automation doesn’t have to be expensive, risky, or disruptive. When done systematically (and with people in mind) it becomes a catalyst for better work, better throughput, and better business.

Cascade Coffee went from manual palletizing with high turnover to a fully automated, highly engaged team that’s confident, growing, and ready to take on more.

Their journey is exactly why we believe in Lean Robotics: start small, scale fast, and build capability through every phase: design, integrate, operate.

Ron said it best:

“You gave us the first steps. We wouldn’t be pursuing automation this aggressively without that early success.”

And that’s the kind of impact we want every manufacturer to experience.

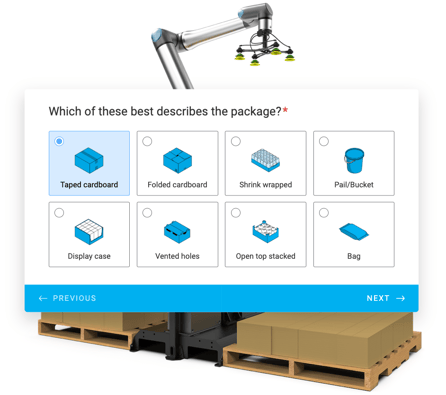

If you want to see whether palletizing automation makes sense for your facility, start with the Palletizing Fit Tool — a quick, interactive way to see if Lean Palletizing is the right match for your line.

Want more stories from real factories like yours?

Follow Robotiq on LinkedIn and join over 75,000 manufacturers seeing how automation keeps people safe, and production running strong.

![]()

-2.jpg)

The post “Inside Cascade Coffee’s playbook for sustainable, scalable automation” by [email protected] (Samuel Bouchard) was published on 11/20/2025 by blog.robotiq.com