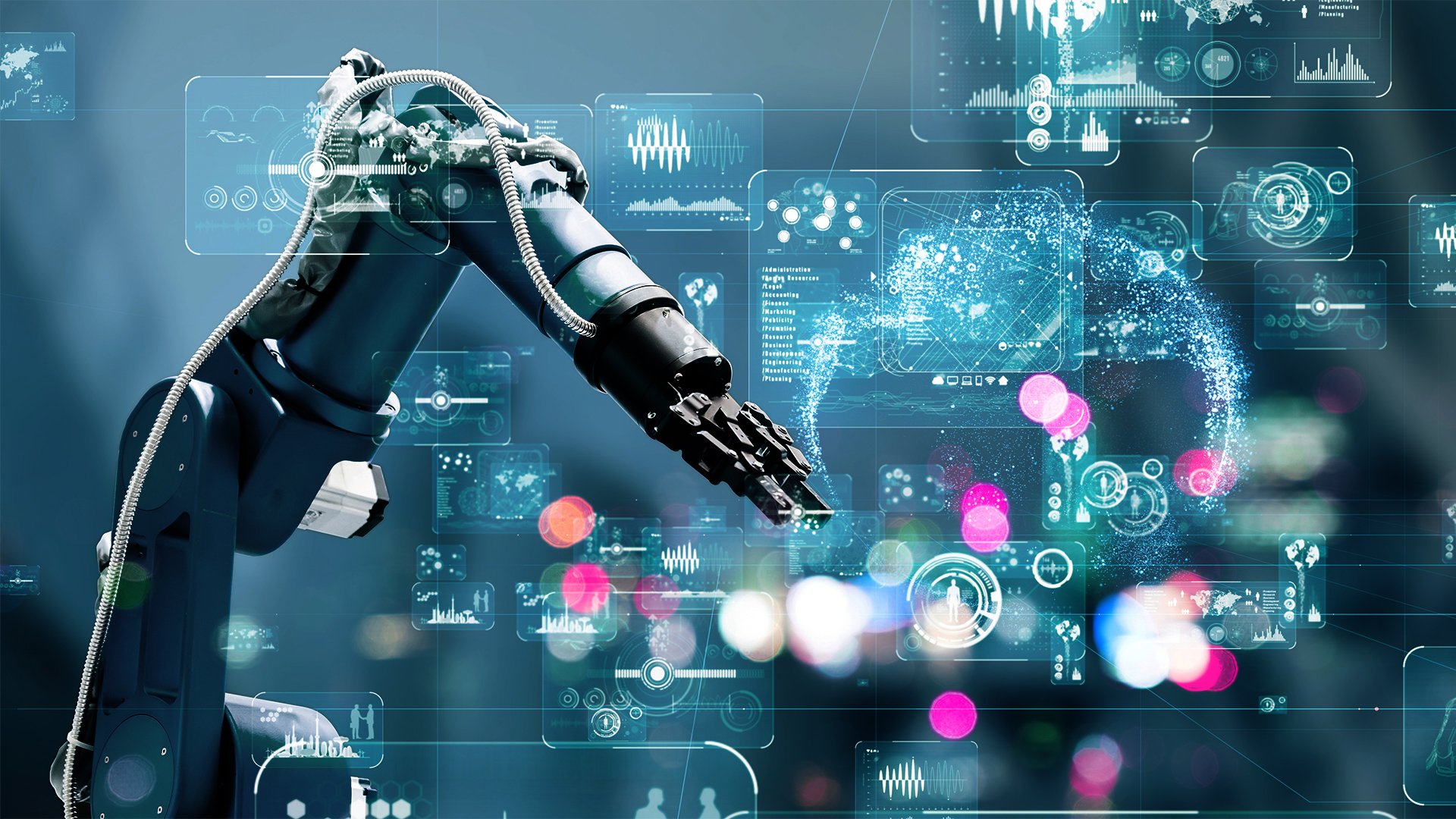

The video “Spot at Chevron | Boston Dynamics” explores the use of advanced robotics technology at Chevron’s facilities. The team at Chevron has been working on integrating ground robots, specifically the Spot project with Boston Dynamics, into their operations. The robot, equipped with a thermal camera, high definition PTZ, acoustic leak detector, and gas detector, is used for inspections, allowing the team to gather data to better inform their decision-making processes. By utilizing robotics for routine duties, such as visual inspections and leak detections, Chevron is able to gather quantitative and reliable data, leading to better decision-making and improved reliability.

The use of computer vision modeling helps filter out unnecessary data, allowing the team to focus on valuable information that can drive their decisions. The video emphasizes the importance of leveraging technology to get better quality information regularly, which in turn enables Chevron to make better decisions. The company’s investment in mobile robotics showcases their commitment to modernization and staying ahead of market demands and competition.

Overall, “Spot at Chevron | Boston Dynamics” provides a fascinating look into how robotics technology is transforming operations at Chevron, allowing for safer, more efficient, and data-driven decision-making processes.

Watch the video by Boston Dynamics

Author Video Description

Companies are facing evolving market demands, regulatory pressures, and competition from alternative energy sources. For Chevron, this means leveraging the company’s strengths to advance new products and solutions that improve reliability and lower the carbon intensity of their operations around the world. Modernization is a key component in tackling these challenges and driving competitive advantage. Chevron has established itself as a leader of the pack with a groundbreaking investment in mobile robotics.

Learn more: https://bostondynamics.com/case-studies/meet-chevrons-new-energy-watchdog/

Video Transcript

Working with robots is my passion whether it’s a ground robot or flying drone I just enjoy working with robots and Robotics and seeing how we can leverage technology how can we use ground robots to get information that today we can’t either safely or economically collect and so I joined

This team and really fell into the spot project with Boston Dynamics and what I’ve been doing the last few years is working on operation Robotics and trying to put Technologies in people’s hands out in the field that would make their job easier and give them better data and

Also help them take out out of Harm’s Way it has a thermal camera a high defin pan tilt Zoom PTZ a acoustic leak detector and then a gas detector for safety and a liar to help it navigate that robot is used for inspections we’re walking around and looking at gauges

Looking at thermal imaging to get tank levels allow us to look at Transformers and see which ones are nearing end of life before they actually have any indication of failure we can look at different pumps and see why is this motor running hotter than this motor or

Why is this pump warmer than this other one right next to it so one of our big ones here is ordd it’s an operator routine Duty and it’s the basic things you do every day right going around sight smell here we take a look at our equipment most of the time it’s been

Pretty qualitative and not quantitative so we go around we say hey did this sound different no cool check the box but now what’s F it’s hey let’s actually go take an acoustic measurement and then we can vet it same thing for temperatures hey is this hot or not yeah

Yeah it’s about the same right but no let’s take a measurement and actually see and Trend that data and same thing with visual inspections we do leak detections here real basic make sure it’s not leaking right but now you can get video and photogrametry and recordings on it and it really helps us

Be more more predictive have better decision making reliability and help Drive our decisions here so we know that we’re doing the right thing at the right time by having more reliable data what I can do is understand sooner what might be going wrong and so sometimes the

Changes that we might be looking for are so subtle but by doing this you know consistently every time and and with great Precision you can basically back out your understanding of what’s going on months 3 months 6 months 9 months and just make better decisions the more that

We learn and the better that we get you know the better our decisions are and just the faster we can we can make changes computer vision modeling allows us to take our people and instead of going through all of the data that’s collected we can focus on just the data

That’s collected that actually provides value 99% of the time we’re collecting all of this data because we need to know if it’s different but 99% of the time it’s not it’s almost all always right but that one time it is you need to know and so if we can use computer vision

Machine learning to automate the processing of this information in the background we can then take that task and not require our people to look through all these images all of this data whether in the field or virtually and instead just alert them that 1% of time that they actually need to know it

And give them the right data at that time to make the decision they need how can we get more information and better quality information with higher regularity to allow us to make better decisions every day dreaming about what you can do and how you could operate everything differently and then making

That dream a Reality

Video “Spot at Chevron | Boston Dynamics” was uploaded on 02/20/2024 to Youtube Channel Boston Dynamics