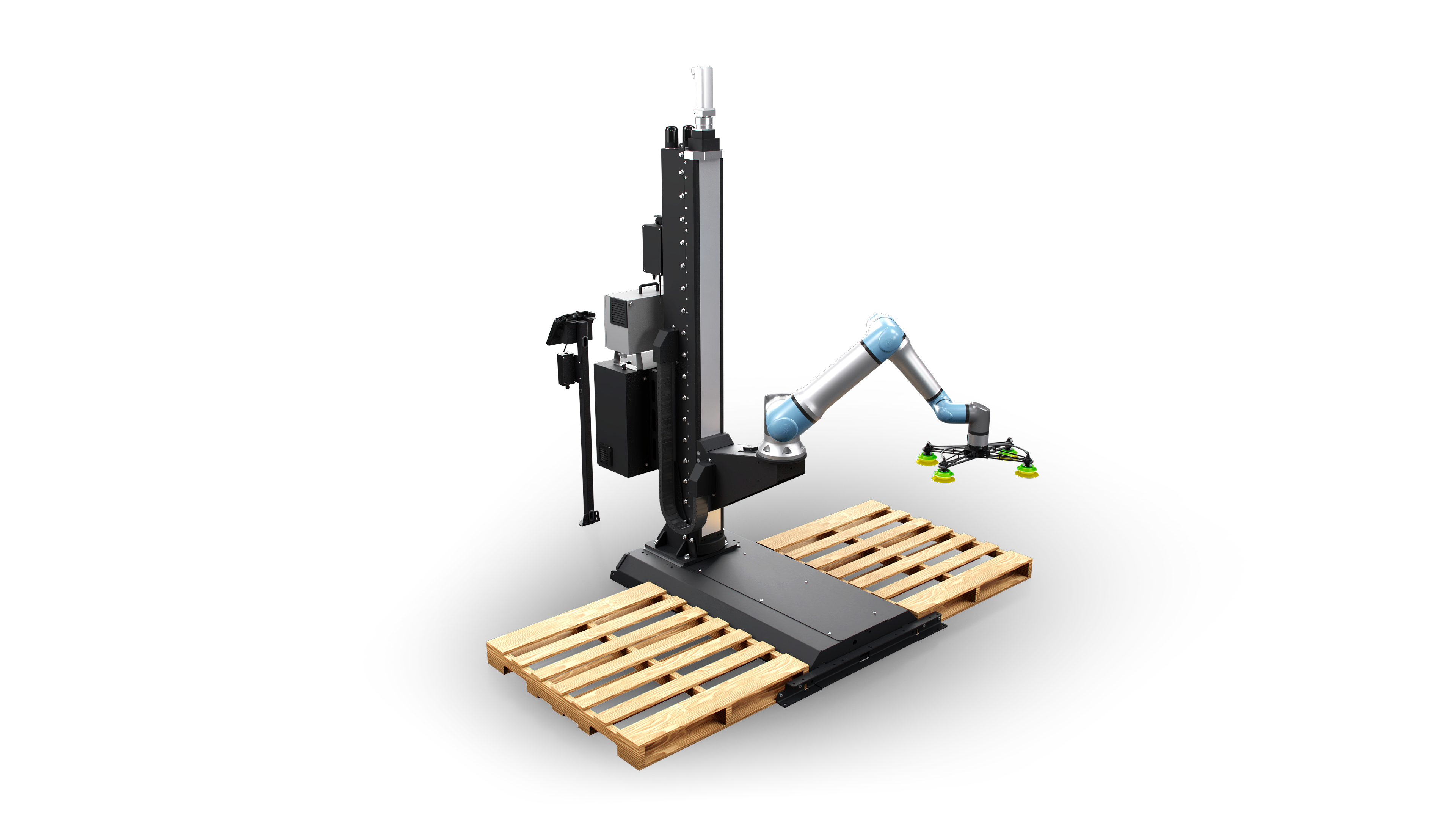

Some wins start with a product demo. Others start with a follow-up. This one started with a dry ingredient factory in Chile and a global initiative to reduce contamination and human error. But what made it all click was the launch of the Robotiq AX30 Palletizing Solution.

A familiar face with a new goal

This customer is known for manufacturing soft drinks—but not at this facility. Here, they produce the dry ingredient blends that make up the secret recipes.

Because of how sensitive those ingredients are, the company had a clear directive:

Automate wherever possible to reduce human interaction and prevent contamination. The fewer hands in the process, the better.

They also wanted to minimize human error and address ergonomic risks since operators were manually handling 22 kg (50 lb) boxes at the end of the line. Not ideal.

Why now?

Funny enough, this wasn’t our first interaction with them. A while back, our partner helped them deploy a case forming application using a collaborative robot. They loved the simplicity and layout flexibility. But at the time, our palletizing solution didn’t have the payload they needed.

Fast-forward a bit, and we’ve got the AX30, which can handle up to 32kg (70 lb).

A tighter fit than industrial

When I visited the plant again, I was worried. The product is expensive, the process is precise, and I assumed we might be going head-to-head with an industrial robot.

But then I saw the floor.

There simply wasn’t enough space to install a traditional palletizer. Between the tight layout and safety concerns, it was clear they needed something compact—and collaborative.

Our AX30 model checked every box:

✅ Safe, ergonomic solution

✅ Compact footprint

✅ Handles their payload needs with ease

✅ Fast to deploy

✅ No major layout changes needed

From “not yet” to “let’s go”

We ended up closing the deal for three AX30 units. The customer was thrilled, not only because we could meet their needs, but because the solution was collaborative, simple, and already proven in their environment.

Even better? Our partner is setting up a display of the AX30 in their own facility. They’ll run customer demos and use this win to inspire others in the region.

Final thoughts

This win wasn’t about checking a box. It was about aligning with the customer’s broader goals—cleaner processes, fewer risks, and long-term flexibility.

And thanks to our partner, their trust in Robotiq, and the power of the AX30, we turned a tight space into a strategic deployment.

Want to see if Robotiq Palletizing Solutions can fit your factory needs? Answer a series of questions to find out in a matter of minutes!

![]()

The post “When small space meets big goals” by Juan Manuel Herrera Medina was published on 07/15/2025 by blog.robotiq.com