Cosmetic manufacturers are under growing pressure to scale output. New product launches, shorter lifecycles, private labels, and seasonal demand are stretching production teams thin. At the same time, labor shortages and rising costs are making it harder to staff end-of-line operations reliably.

For many manufacturers, the bottleneck isn’t filling, labeling, or packaging. It’s palletizing.

That’s why more cosmetic manufacturers are turning to collaborative robot (cobot) palletizing as a practical, scalable way to increase throughput—without rebuilding their plants or locking themselves into rigid automation.

The end-of-line challenge in cosmetics manufacturing

Palletizing remains one of the most manual and labor-intensive steps in cosmetic production. In many facilities, it still requires:

- One operator per line

- Multiple shifts per day

- Repetitive lifting and twisting

At the same time, cosmetics manufacturers face a uniquely complex operating environment:

- High SKU variety

- Frequent carton and pallet pattern changes

- Limited floor space near production lines

Traditional industrial palletizers struggle here. They’re often oversized, expensive, and designed for long runs of identical products—conditions that don’t reflect today’s cosmetics operations.

Why cobot palletizing works in high-mix cosmetics environments

Cobot palletizing flips the traditional automation model.

Instead of relying on one large, centralized palletizer, manufacturers can deploy compact palletizing cells directly at each production line. This decentralized approach fits the realities of cosmetic manufacturing.

Key advantages include:

Flexibility

Cobots handle multiple SKUs, box sizes, and pallet patterns with minimal reconfiguration. Recipe changes don’t require expert programmers or long downtime.

Compact footprint

Designed for tight end-of-line spaces, cobot palletizers integrate easily into existing layouts without major facility modifications.

Ease of operation

Operators can manage pallet changes and basic adjustments with minimal training—critical in environments with frequent staff rotation.

Lower deployment risk

With no heavy fencing or complex infrastructure, cobot palletizing is faster to install and easier to justify internally.

For many cosmetics manufacturers, this is the first time automation feels achievable rather than disruptive.

Fast ROI without over-automation

Return on investment is a major driver behind cobot palletizing adoption.

In a typical cosmetics facility:

- Palletizing requires one operator per shift

- Lines often run two or three shifts

- Labor costs scale linearly with production

By automating palletizing at the line level, manufacturers can often reach payback in 12 to 24 months, while keeping capital investment aligned with real production volumes.

Instead of committing to a single, high-cost system upfront, they can:

- Start with one line

- Validate performance

- Expand automation progressively

This approach reduces financial risk and avoids over-automation—an important consideration in fast-changing cosmetic markets.

A scalable model for growing product portfolios

Cosmetic brands evolve constantly. New formats, new packaging, new SKUs.

Cobot palletizing supports that reality through modularity and repeatability. Once a solution is validated on one line, it can be replicated across:

- Additional production lines

- New product families

- Future plant expansions

This creates a standardized automation model that grows with the business, rather than constraining it.

Supporting people while scaling production

Cobot palletizing isn’t about replacing workers—it’s about using skilled labor where it matters most.

By removing repetitive end-of-line tasks, manufacturers can:

- Reduce physical strain and injury risk

- Improve consistency and pallet quality

- Reassign operators to higher-value roles

As labor availability becomes less predictable and product complexity continues to rise, cobot palletizing is increasingly viewed not as optional—but as a strategic enabler of sustainable growth in cosmetics manufacturing.

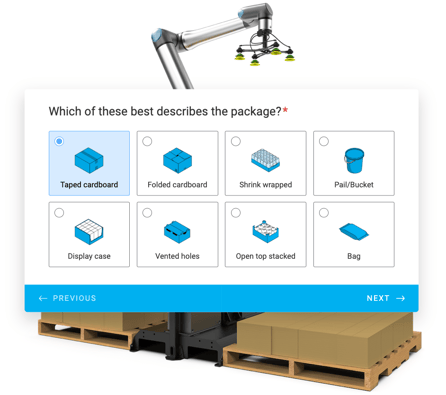

Is cobot palletizing the right fit for your cosmetic production line?

Not every line has the same requirements. Payload, cycle time, SKU mix, and available space all matter.

Use Robotiq’s Palletizing Fit Tool to quickly assess whether cobot palletizing makes sense for your operation and what a realistic deployment could look like for your facility.

Want more stories from real factories like yours?

Follow Robotiq on LinkedIn and join over 75,000 manufacturers seeing how automation keeps people safe, and production running strong.

![]()

The post “How cosmetic manufacturers are turning to cobot palletizing to scale production” by Élisabeth Ste-Marie was published on 01/15/2026 by blog.robotiq.com