When most people think of installing a robotic cell, they imagine a process that takes half a year, maybe more. Endless design reviews, integration delays, and operator training that drags on for weeks.

But it doesn’t have to be that way.

With the Lean Robotics methodology, we’ve seen manufacturers go from “we should automate” to a fully running robotic cell in as little as 90 days. Here’s how.

Why speed matters

Time is money. The faster you deploy automation, the sooner you:

- Reduce labor bottlenecks

- Improve throughput

- Capture ROI

Long timelines kill momentum. They drain enthusiasm from your team, delay your return, and in some cases, stall the project entirely.

That’s why a structured, time-bound approach is key.

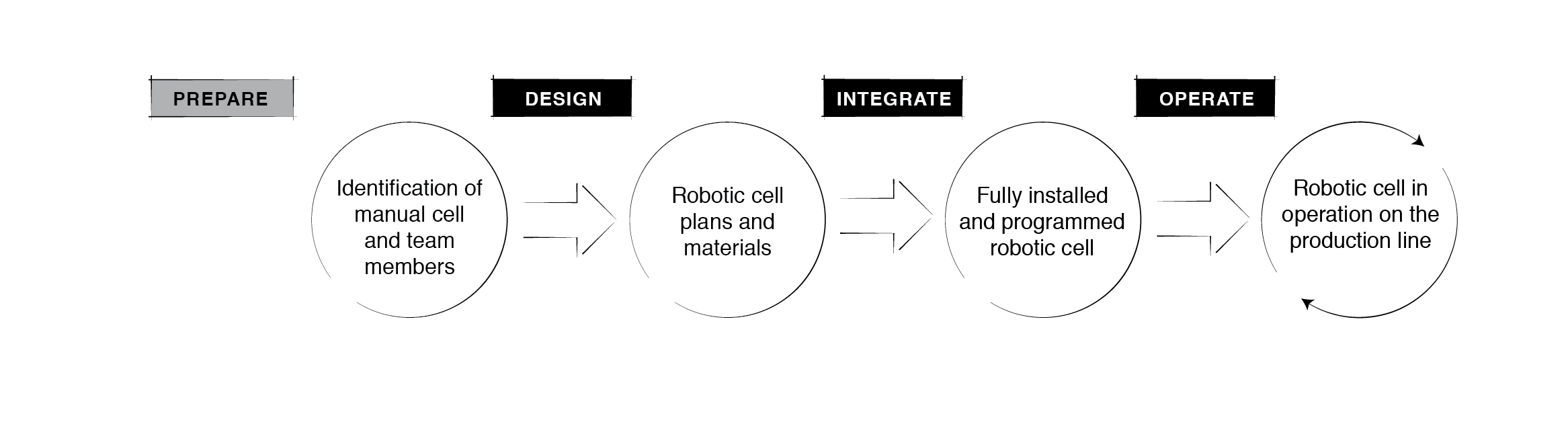

The Lean Robotics 90-day roadmap

Month 1 – Design

Instead of starting with the robot, start with your cell’s output.

- Define the “customer” for your cell (often the next step in the process).

- Determine the quantity, quality, and pace that process needs.

- Design your layout for flow, safety, and ease of use.

Pro tip: Avoid overengineering. Focus only on the features you need for this phase of production. You can always expand later.

Month 2 – Integrate

This is where you turn the plan into reality:

- Assemble your cell with standardized, pre-tested components where possible.

- Program offline to save on production downtime.

- Test with realistic production inputs—don’t wait until installation to discover issues.

Pro tip: Keep integration lean. Overcomplication at this stage leads to delays and future headaches.

Month 3 – Start to operate

Once the cell is installed, it’s time to:

- Train operators for confidence and comfort, not just compliance.

- Run at low volume first, gathering feedback from your team.

- Optimize based on real-world performance before scaling to full output.

Pro tip: Document everything—layouts, programs, SOPs—so your next cell goes in even faster.

What you gain by moving fast

- Quicker ROI – You start saving sooner.

- Team buy-in – A short, successful deployment builds confidence for future automation.

- Standardization – Lessons from your first 90-day project become the blueprint for the next.

Lean Robotics makes it possible

The 90-day timeline is about removing the waste that slows projects down. With the right framework, tools, and mindset, your team can go from blank floor space to a productive robotic cell in just three months.

Want to see how this could work in your factory?

👉 Take a deep dive into these principles with your FREE digital version of the Lean Robotics book (or order a physical copy!)

👉 See if a Robotiq Palletizing Solution is a good fit for your factory. Simply answer a series of questions and we’ll send you a customized 3D simulation and report showing exactly which solution matches your factory space and needs in just a matter of minutes!

![]()

The post “From blank floor space to a running robotic cell in 90 days” by [email protected] (Samuel Bouchard) was published on 08/12/2025 by blog.robotiq.com